Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

Are you currently looking to easily track product, control your process flow, deliver the exact document to your factory floor, and collect quality data? Find out below if CELLS Workflow MES is what you have been looking for.

CELLS Workflow MES from Unisoft is a Process Control Software System designed for electronic manufacturers and other industries. CELLS Workflow MES provides the following benefits:

CELLS Workflow MES puts you in control. CELLS Workflow MES answers these questions: Where does this unit go next? Is this the most current revision? What documents are associated with this unit? What do I do now? When will my work order be completed? How many times has this unit failed before?

CELLS Workflow MES is a mature software product that has tracked millions of transactions for our clients. CELLS Workflow MES is proven in the most stringent environments such as FDA audited class 1 medical electronic device manufacturers. Yet CELLS Workflow MES is simple to set up, in less than a day you can be using CELLS Workflow MES to improve quality, control process, aid ISO-9000 requirements and increase your company's bottom line.

Logging on to CELLS Workflow MES can be individually password protected. Additionally grouping is allowed to aid in qualifying the employee performing an operation (QA, inspection, repair group, etc.).

Log On

You can open units by one of the following methods:

Open by Serial Number

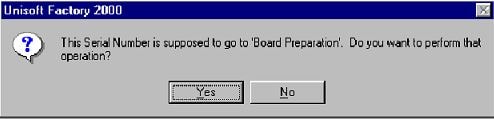

By serial number is the most common way to open a unit. After the serial number is scanned or entered manually, CELLS Workflow MES then goes through a series of checks to see if the operator is authorized to access the system.

Check the next step operation

If the operator is the correct person to perform the next step CELLS Workflow MES will then:

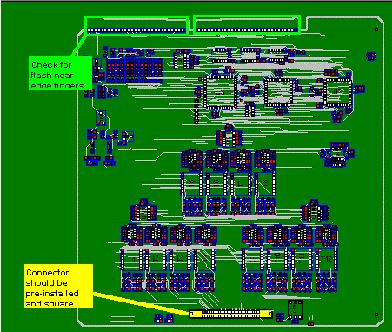

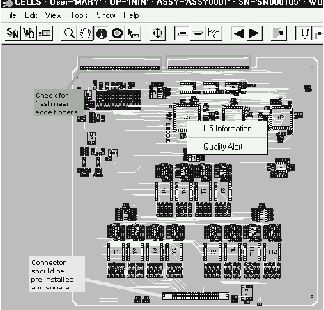

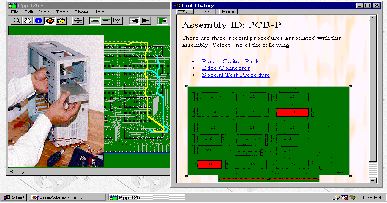

The exact documents are delivered to each operation step to aid the individual in doing their job. CELLS Workflow MES points to the document location so you are assured only the latest revision is delivered automatically.

CELLS Workflow MES has a flexible delivery system to send virtually any type of document from any source to your factory floor. CELLS Workflow MES allows either direct file link or via web browser pages. Also, template type overlays can be added to the current display to show annotations, highlighted areas, etc. Documents can be associaed in multiple ways, for example with the whole unit, a specific part number, or just a single item or component.

Example of overlays and annotations

Hot spot any area of the display or just a single

item or component. Specification information is automatically available behind every

item or component.

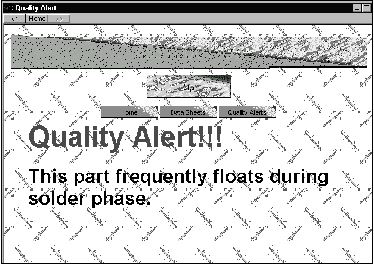

Example of web browser — Deliver a single web page or an entire

internal intranet.

Example of web browser — Use all the rich components of the web such as text, graphics, multimedia (movies / audio), email, Java, plugins, etc.

You may wish to view the history of a unit to see where it's been, what's been done to it, or the defects that have occurred. CELLS Workflow MES provides you an easy way to find that information in an open database environment (ODBC).

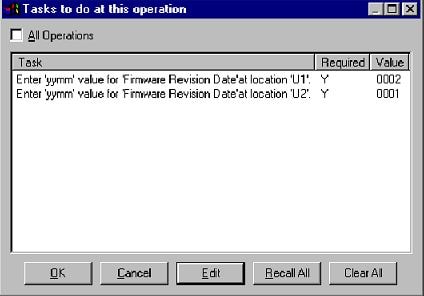

If the operation step calls for it, CELLS Workflow MES creates a task list with required items to be completed.

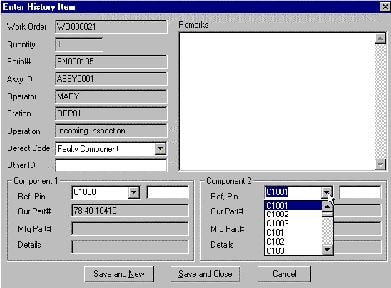

CELLS Workflow MES provides accurate and quick logging of defects. All defect codes specific to each operation are available. Select the type of problem and it is logged automatically.

Moving to the Next Step — Typical options for movement are Pass, Electrical Failure, Mechanical Failure, Scrap, Sub-assembly complete, Send to stock, etc. CELLS Workflow MES routes and tracks the unit accordingly.

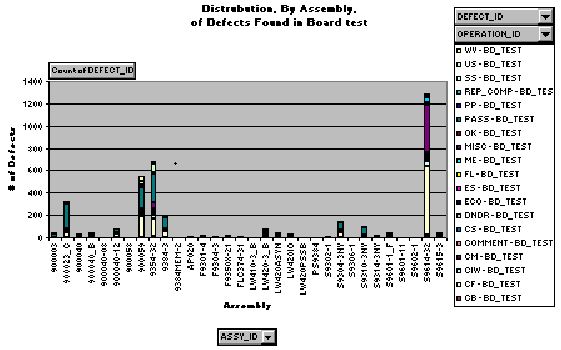

Once CELLS Workflow MES has collected work in progress (WIP), failure/quality or other data, you can create reports against it using standard reports supplied within CELLS Workflow MES or create your own reports using MS Access, MS Excel, SAS, Crystal Reports, etc. (You may use any report writer or analysis tool that supports ODBC.) You can even publish the reports to your CELLS Workflow MES intranet or provide dynamic report generation through CELLS Workflow MES or any web browser.

Have questions or want more information? Contact us.